3D laser cutting and welding

Our new 3D laser cutting and welding system TRUMPF TruLaserCell 7040 is an advanced system for sheet metal processing.

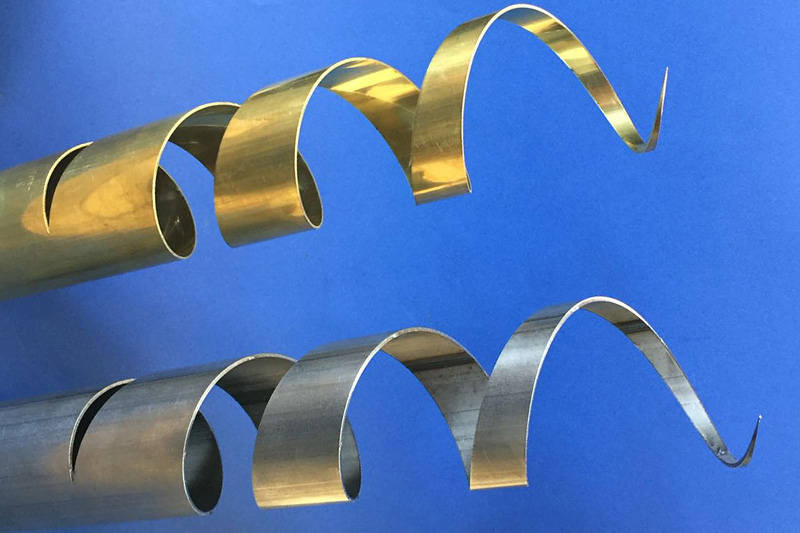

We make 3D cutting and 3D welding of deep-drawn and stamped sheet metal, two-dimensional or three-dimensional sheet metal, tubes and profiles.

Thanks to the high versatility of the machine, it is possible to make laser cutting and welding, with or without deposit material, of two or more different parts.

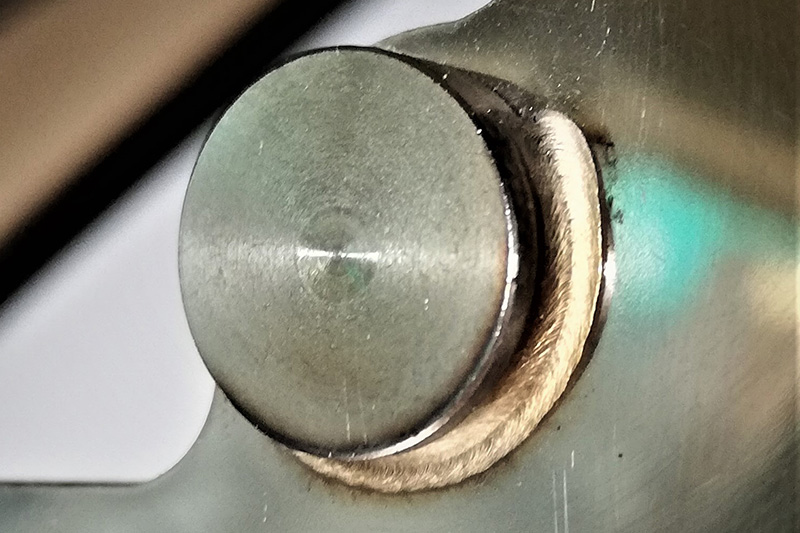

Laser welding is a state-of-the-art method that guarantees quality and accuracy of welds.

The laser welding is able to weld very thin sheets, less than 1mm thickness, with excellent quality and aesthetics.

Thanks to the 4000W fiber laser source, we can process steel, stainless steel, galvanized steel, copper, aluminum and other materials.

WELDING METAL COMPONENTS

The laser processing of three-dimensional components, by laser welding, allows us to design and obtain new geometries that can not be obtained with different machining operations. It allows manufacturing components by saving material and getting weight reductions.

Laser welding avoids distortion of the component, an important factor in metal welding of solid geometry, and more so in welding sheet metal

Compared to traditional processes, with laser welding we obtain aesthetically unequalled quality, getting obsolete the work of cleaning and finishing of welding

CUTTING DEEP-DRAWN COMPONENTS

TRUMPF TruLaserCell 7040 we can make the trimming and the openings of deep-drawn components. Often the processing with traditional punching tools is too expensive. With the TRUMPF TruLaserCell 7040, we can cut all the required contours in a short time, thus reducing production costs

AUTOMOTIVE INDUSTRY

The laser cutting and welding 3D with the TRUMPF TruLaserCell 7040 is used in the automotive industry to process deep-drawn components made of steel or galvanized steel to protect them against corrosion. With TRUMPF TruLaserCell 7040, we can cut galvanized steel sheets quickly and to the highest quality level. In addition, the machine allows us to respond optimally to changes and to adapt the component accordingly. This increases flexibility, a particularly important element for prototype production and pre-production.

PRECISE AND FAST DIE CAST LASER CUTTING

Compared to traditional processes such as milling, our 3D laser cutting TRUMPF TruLaserCell 7040 is a valuable cost-effective alternative for these components (for example die-cast aluminum). We perform the laser cutting of all through holes and external contours.